A Family Legacy Since 1853

Our foundry, under the ownership of the Peaslee family since 1939, boasts over 160 years of expertise. Operating from an 81,000 sq. ft. facility, we craft exceptional grey, ductile, ADI, silicon moly, and compacted graphite iron castings. With an average of 80 skilled employees, we take pride in our enduring commitment to quality and innovation.

A Family Legacy Since 1853

Our foundry, under the ownership of the Peaslee family since 1939, boasts over 160 years of expertise. Operating from an 81,000 sq. ft. facility, we craft exceptional grey, ductile, ADI, silicon moly, and compacted graphite iron castings. With an average of 80 skilled employees, we take pride in our enduring commitment to quality and innovation.

Our mission is to provide our customers with defect-free castings, at a competitive price, that meet or exceed their requirements for quality and delivery.

In 2009, MGIF became one of just three U.S. foundries to participate in the Department of Energy’s Better Building Plants initiative, dedicated to energy-saving practices. Since then, we have achieved an impressive 17% reduction in overall energy consumption.

Our commitment to environmental responsibility extends to cutting-edge solutions. We’ve invested in state-of-the-art dust collection and embraced an Advance Oxidation – SonoPeroxide dust recycling system, leading to a significant reduction of over 50% in greensand emissions.

Furthermore, our core machines now utilize phenolic urethane resins within an inorganic binder system, effectively curbing VOCs by an outstanding 50%. At MGIF, we take pride in preserving the planet while delivering top-quality products.

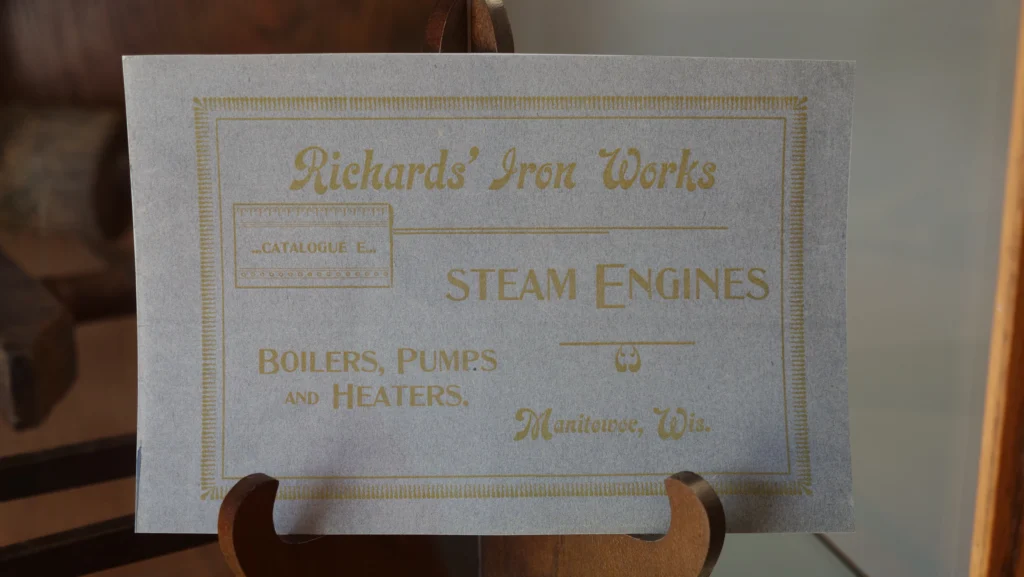

With roots dating back to pre-Civil War days, Manitowoc Grey Iron Foundry (MGIF) carries a rich and enduring history. The journey began when Jonah Richards founded the original foundry in the year 1853. Located in Manitowoc, Wisconsin, the foundry played a vital role in producing essential parts for the numerous ships built during the early years of the town’s history.

Tragically, Jonah passed away at the young age of 53 in 1881, leaving his son, Henry, to take the reins of the business. Under Henry’s leadership, the foundry thrived, particularly during the challenging years of World War I. However, the company faced a setback when Henry unexpectedly passed away in 1924, leading to the foundry going into receivership.

Over the next 18 years, the foundry changed hands multiple times, with different owners overseeing its operations. In 1942, Robert Fox leased the foundry and reestablished it as Dunrite Industries. Once again, the foundry’s fortunes improved, buoyed by the demands of World War II.

However, it was in 1946, following the end of WWII, that a pivotal moment arose when Robert Fox invited his nephew, John B. Peaslee, to join him in the business. Within a short period, John took over the company, renaming it Manitowoc Grey Iron. The year was 1947, and the foundation was laid for a family-owned and operated enterprise that would endure through the decades.

In 1952, MGIF moved to its present-day location at 2701 Division St., Manitowoc, WI. As time passed, John’s dedication and vision bore fruit, and the foundry continued to expand and evolve.

Joining him in the business were his two sons, Robert and Jay, who, after graduating from college, embraced the family legacy. Later, his daughter, Alison, also became an integral part of the company.

Throughout the years, MGIF witnessed significant transformations in its manufacturing processes. Originally employing a cupola and coke to melt iron, the foundry made notable progress in 1974 when it introduced channel furnaces. In 1998, these furnaces were replaced by coreless furnaces, demonstrating the company’s commitment to innovation and efficiency.

Today, Manitowoc Grey Iron Foundry stands as a testament to hard work, dedication, and the power of a united family enterprise. It crafts a diverse range of iron castings, including gray, ductile, ADI, silicon moly, and compacted graphite iron, serving customers across the Midwest. The foundry’s unwavering commitment to quality, continuous improvement, and ethical practices has allowed it to thrive for generations.

With a team of about 80 skilled and passionate professionals, MGIF remains firmly rooted in its heritage while embracing the future. As it embarks on new horizons and forges ahead with unwavering determination, Manitowoc Grey Iron Foundry continues to make its mark on the ironworks industry, embodying a legacy that spans over a century and will undoubtedly endure for many more years to come.

Join CEO Rob Peaslee as he takes you on an engaging journey through our foundry’s storied past and remarkable heritage.

1853 – Jonah Richards opens the original foundry as Richards Iron Works

1881 – Jonah passes away and his son, Henry Richards takes over

1924 – Henry passes away and the company goes into receivership

1924-1942 – The foundry passes hands several times

1942 – Robert Fox leases the foundry under the name of Dunrite Industries

1946 – John B. Peaslee, Fox’s nephew, joins the business

1947 – John buys the company from his uncle and renames it Manitowoc Grey Iron

1952 – MGIF moves from its original site to its current location

After 1952 – John’s children, Robert, Jay and Alison join the business

1974 – The foundry changes from cupola and coke to channel furnaces to melt iron

1998 – The channel furnaces are replaced by coreless furnaces